Test transformers are necessary test equipment for power equipment testing and preventive tests. With the development of my country’s power industry, the requirements for the voltage level of test transformers are getting higher and higher. However, traditional oil-immersed test transformers are increasingly unable to meet the requirements of on-site work in terms of volume, weight and performance. Require. So, what are the precautions for the gas-filled test transformer during and after the test?

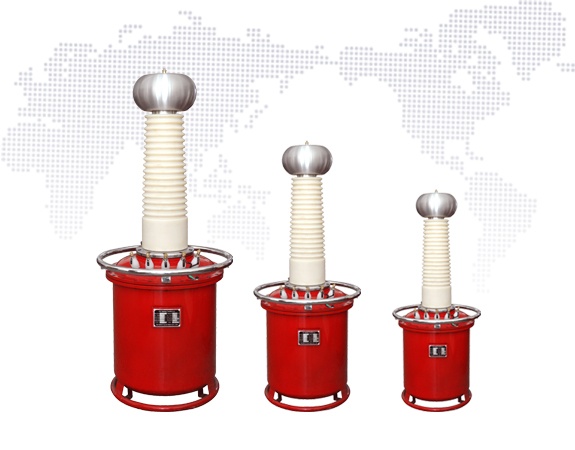

HV HIPOT Gas-type test transformer

1. During the transportation of the equipment, because of the high-pressure gas filled inside, it should be handled with care, especially not to damage the casing.

2. The layout of the test equipment should have a sufficient safety distance around the person. Try to avoid arranging equipment and applying high voltage leads on the personnel aisles.

3. Fences are installed at the test site, and signs of “stop! high voltage danger” are hung on the test site.

4. In the test, the high-voltage leads must have support or pull insulators. Have a safety guard to prevent people from approaching and passing underneath.

5. When the microammeter is in the high position in the DC high voltage test, in addition to the shielding box, there should be an automatic overcurrent protection device to prevent sudden breakdown and short circuit or burnout of the meter during discharge.

6. Power frequency withstand voltage test: Please check whether the capacity of the equipment is sufficient and avoid resonance.

7. The working ground wire (high voltage tail, the ground wire of the stabilized capacitor end) and the protective ground wire (operating box shell) should be connected separately and have good grounding performance.

8. If there is irregular power swing (such as electric welding) during the test, it will inevitably affect the stability of the high-voltage output. At this time, the test should be stopped to find out the cause and eliminate it.

9. HV Hipot’s requirements for climate (temperature, humidity) in the test work shall meet the requirements of the test regulations and record.

10. The high-voltage test work must strictly implement the relevant regulations of the safety work regulations issued by the Ministry of Energy.

Maintenance :

1. The test transformer should be kept clean regularly, and the nylon sleeve should be wiped clean before each test and covered with a plastic cloth.

2. Do not twist the bolts other than the wiring support at will to prevent air leakage caused by the damage of the seal.

3. Slight leakage is a normal phenomenon. It is estimated that the air pressure will decrease by 0.05Mpa every 4 years, and the air pressure at the factory will be between 0.1-0.3Mpa. As the environmental humidity changes, the air pressure slightly increases or decreases. When the air pressure drops to 0.1Mpa, the air should be supplemented.

Post time: Dec-16-2021